Introduction

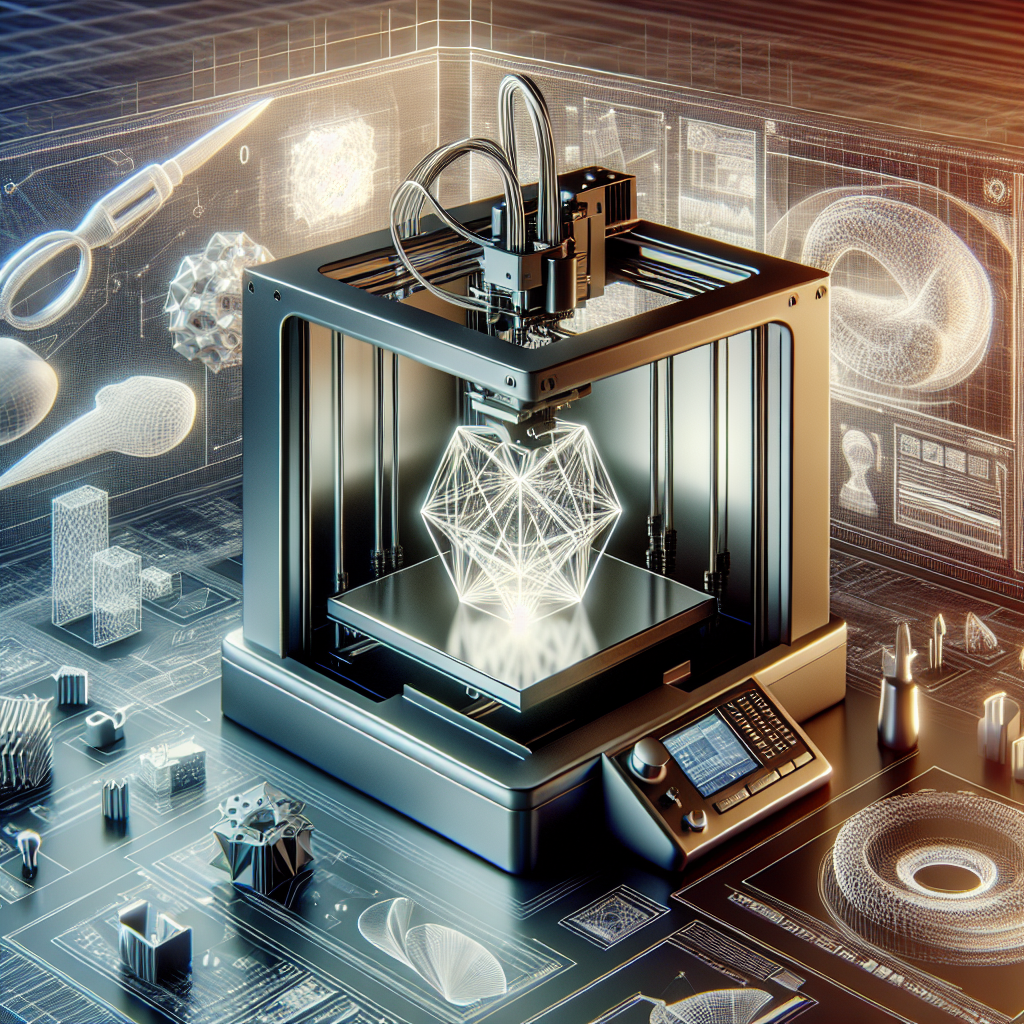

3D printing, also known as additive manufacturing, is revolutionizing the way products are designed, developed, and produced. This technology allows for the creation of three-dimensional objects from a digital file, using layer-by-layer deposition of materials. As it continues to evolve, 3D printing is reshaping product development across various industries.

Advantages of 3D Printing in Product Development

- Cost-Efficiency: 3D printing significantly reduces material waste and manufacturing costs, making it an attractive option for startups and established companies alike.

- Speed: The rapid prototyping capabilities of 3D printing allow designers to create functional prototypes in hours rather than weeks, accelerating the product development cycle.

- Customization: Businesses can easily customize products to meet specific customer needs, enabling personal touches that traditional manufacturing methods cannot accommodate.

- Complex Design Possibilities: 3D printing allows for intricate designs that are often impossible to achieve with conventional methods, opening up new avenues for innovation.

- Reduced Supply Chain Complexity: With the ability to produce items on-demand, companies can minimize inventory costs and reduce reliance on complex supply chains.

Applications of 3D Printing in Different Industries

1. Healthcare

In the healthcare sector, 3D printing is being used to create personalized medical devices, prosthetics, and even bioprinted tissues. Surgeons can practice procedures on 3D-printed models of their patients’ organs, enhancing precision and outcomes.

2. Aerospace

The aerospace industry is leveraging 3D printing to manufacture lightweight parts that enhance fuel efficiency. Customized components and rapid prototyping allow for quicker development of advanced technologies.

3. Automotive

Manufacturers in the automotive industry use 3D printing for prototyping vehicle parts and even producing end-use components, improving both design efficiency and performance.

4. Consumer Goods

Companies are creating personalized products, such as jewelry and home decor, tailored to individual customer preferences, which boosts customer satisfaction and engagement.

The Future of 3D Printing in Product Development

The future of 3D printing in product development looks promising. With ongoing advancements in materials science and printing technologies, we can expect to see:

- Enhanced Materials: New materials, including biomaterials and recycled plastics, will be developed for 3D printing.

- Greater Automation: Increased automation in the printing process will facilitate faster production and higher precision in manufacturing.

- Integration with AI: The application of artificial intelligence will optimize design and production processes, enabling smarter manufacturing solutions.

Conclusion

3D printing is undeniably changing the landscape of product development. Its ability to offer cost-effective, rapid, and customizable solutions makes it an essential tool for innovation across various industries. As technology continues to advance, the potential for 3D printing will only expand, paving the way for a new era of product development.